Tool #37

I firstly came across KANBAN in my studies at university. At the time, the world was driven by Japanese thinking. Toyota was setting the standards in organizing and evolving business. We all had to read the book "The machine that changed the world," A book on how Toyota became one of the world's largest car companies.

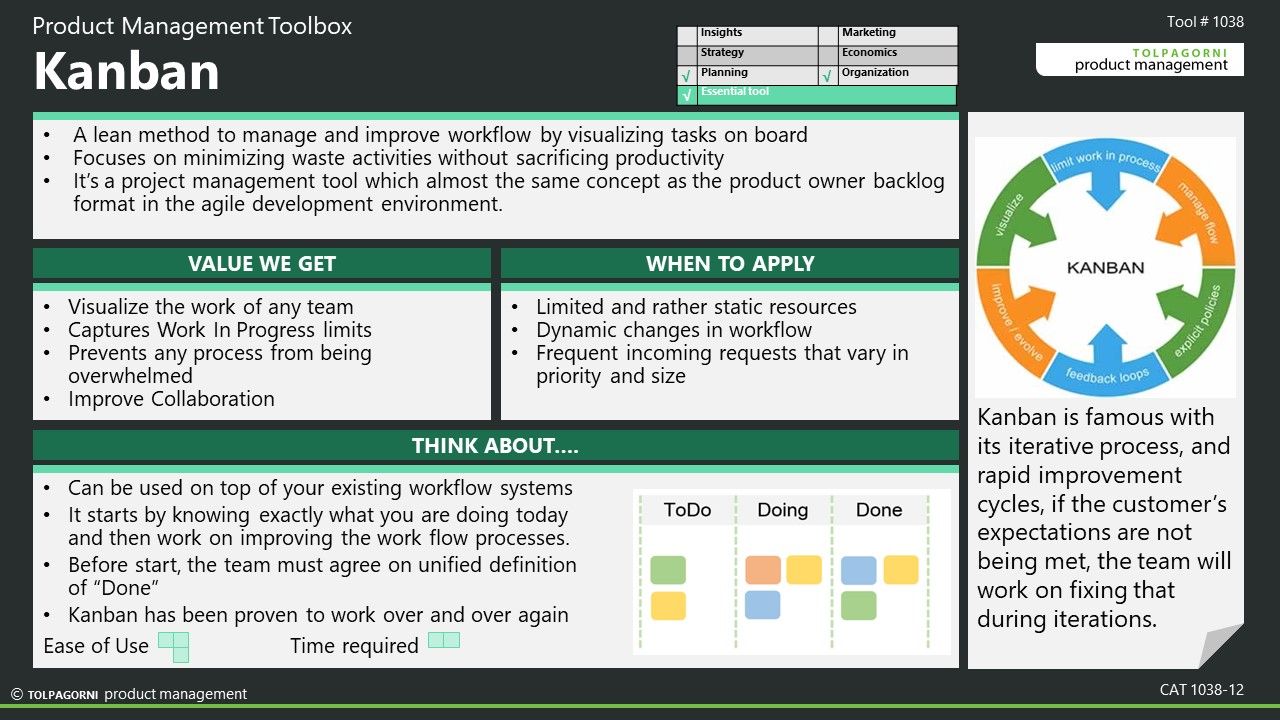

Kanban was also invented at Toyota and is a part of the Lean playbook. How do we minimize waste and maximize output? It is as easy as it is powerful. The principles apply to both agile development environments in production. I have used it both for setting up production lines for computer screens and for building CRM solutions.

The principles are based on human nature. If we overflow a system with items to do, it will slow down. We shall have a steady flow of incoming items to act on to make the process efficient. Each phase has a limit on how many objects we can handle. Kanban is old and will grow older!

Empty space, drag to resize

Empty space, drag to resize

Oops, looks like you're not logged in!

Log in in order to access the tool!

Copyright © 2026 ProductBeats AB

Get The Program Brochure

Submit the form below to have The Program Brochure delivered to your inbox

The title of the notification

The descriptive text of the notification